Function And Characteristic

And use three years of independent research and produce of this new packaging materials manufacturing complete sets of production equpment,

which is divided into two parts:First,EP-1200 buffer column manufacturing machine,individual release and pich up motors make production more

smooth and effective.Release and pick up roll holders are using air expansion shaft,easy load and unload.the second is a EP-800B buffer column bag

forming machine.Both sets of equip-ment together through certain procedures to the production of raw materials into a cushioning packaging material roll film.

Function And Characteristic

1、Automatic Machine controlled by PLC and lnverter.Easy operation control panel.

2、Parameter setting effect immediately,tracked by electronic eyes,smooth and accurate.

3、Widely frequency range of inverters are controlling the whole pro-duction line,stepless speed changing.

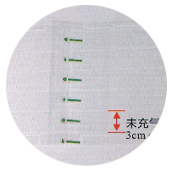

The one air column bag could bear 60-120kg pressure not to burst. it could also protect product breaking not only for air filling and supporting. Compared with the traditional filling material, it could prevent product sliding, and keep a compact packing without spare space, it also could protect the product without collision even if facing external heavy extrsion pressuer, and protect the goods to shift, the air column, the skin design also can use its air cushion to diasperse the pressure and avoid the goods breakage.

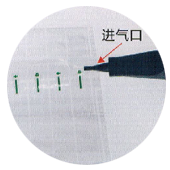

The air column bag could be filled immediately per your wish, The air column bag is consisted of 95% air and 5% film, the bag is smooth before air filing, it does not occupy the space, it could save a lot of cost for storage and trans-portation.

Green environmenttal and recyclable

Buffer column bags have passe CIT, SGS and the EUREACH and other international authoritative organization test, in line with the latest U.S. and EU environmental standards. The raw materials used Biodegradable,non-roxic and toxic heavy metals, in line 7# environment. Whether under the production, use, recycling and other place or any situation, raw materials or finished prodcuts are completely clean and will not cause any pollution, non enbironmental issues arise.

Reduce more than 10% space as to traditional packing

It's thin film before using.Save more than 90% of storage space

Avoid the traditional bubble film packaging,Justneed to inflate the gas column and put the product inside.Save both time and labor